Why Ferrous Chloride is the Perfect Solution for Biogas

Part one of this interview is ‘Sewage Works to Biogas Plants and Ferrous vs Ferric’ where we discuss water treatment in the sewage industry and the differences between chemicals.

Following on from this we explore the beginnings of the biogas market and how ferrous chloride was introduced to solve a number of problems.

The ‘Sewage Works to Biogas Plants and Ferrous vs Ferric’ interview ended on…

Ieuan – The project we supplied was a joint venture between Severn Trent Water and East Midlands Electricity Company. It was during this time that we developed the formula to remove hydrogen sulphide from biogas.

Abbie – Where was this project?

Ieuan – In Wanlip in Leicestershire. They were trying to produce electricity from sewage sludge to put into the grid. I’d done some work with them on septicity control in rising mains which is a similar bacteriological process. Essentially sewage goes into a rising main, out of light, and it uses up all the oxygen contained in the sewage. Then the bugs start to breakdown other chemicals to gain oxygen. Nitrates and sulphates for example will break down to get oxygen out. In doing so you generate hydrogen sulphide (H2S).

Abbie – Was Wanlip one of the first biogas plants in the UK?

Ieuan – It was one of the first to produce electricity to put into the grid, There had been earlier ones, in fact I worked at one in Roundhill but that only produced electricity for the plant. This was the first time they generated enough power to sell to the grid.

Abbie – Why did they contact you?

Ieuan – Severn Trent contacted me because they had a problem with damage caused from corrosion. The CHP unit they had could only tolerate around 200 parts per million of H2S in gas. At the time we had no idea how much would be required to take it out so we increased the dose until we could see the levels coming down. Eventually we fine tuned it and found the relationship between the amount of H2S in the gas above the sludge level and the amount of H2S in the sludge. That ratio is 12-1 so basically every one milligram of iron you have in the aqueous phase (sludge part) will take out 12 in the gaseous phase.

Abbie – Had they been running the plant for a while before they brought you in?

Ieuan – Yes but with limited success because of the damage caused to the CHP unit. When you burn H2S it produces sulfuric acid which rots the pumps, pipes and CHP units.

Abbie – Did you have to do much to the plant to switch over to ferrous?

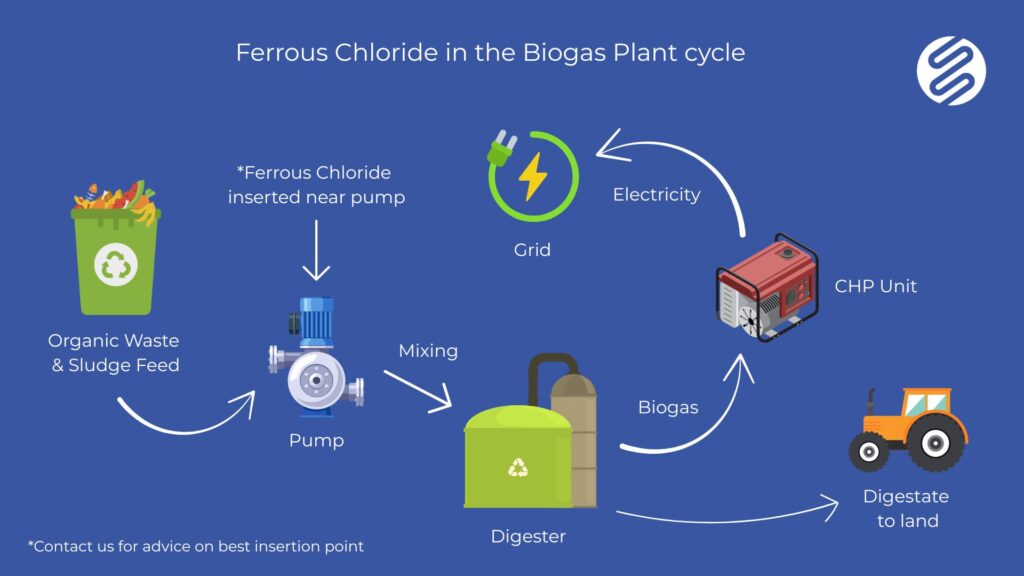

Ieuan – No, nothing. When the sludge comes from the primary settlement tanks it’s quite watery so they wait for it settle. This meant they could skim the water off before pumping into the digester. We then fed the ferrous chloride into the eye of the pump, this gave us very good mixing into the digester.

Abbie – Does this apply across all sites?

Ieuan – Yes, the reason is simple. In order for the bacteria to thrive and live you need a pH between 5.5 and 6.5 and it rarely differs from that. It’s the primary pH for breaking down the carbonaceous material and for your methane bacteria to produce methane. Anything out of that band, one or the other will suffer.

Abbie – Hence it increases the methane yield?

Ieuan – Yes, H2S is poisonous to most bacteria, but to methane bacteria particularly. If you take that out (the H2S) the methane bacteria will thrive. In short, ferrous creates an ideal environment for methane production and it does so without lowering the pH. If you go below 5.5 you start to poison the digester and you’ll get reduction in bacterial numbers until it reaches a critical point when everything will die. That’s the danger with using things like ferric chloride and ferric sulphate, they’ll drop the pH. Ferrous chloride doesn’t.

Abbie – Effectively you’re saying that ferrous is the best option for biogas plants then?

Ieuan – By a country mile. Mainly because the effect on the pH is minimal. Iron will only work when it’s in solution, that’s a chemical fact. Therefore, if you add things like scales and powders to the plant, only 5 to 10% of the iron does the job. Ferrous chloride is already a solution so you can put it straight into the plant, ideally by the pump, and all of the iron gets to work.

Abbie – Is ferrous being a solution what also makes it pipe and pump friendly?

Ieuan – Correct, because there’s nothing to abrade them. Using powders and such like has the same effect as jewellers Rouge. Jewellers rouge is a paste made from iron oxide powder and it polishes by eroding the top layer of metal. Should biogas plants use iron oxide powders for H2S control they’re encouraging corrosion of the pipework.

Abbie – What happened after the success at Wanlip?

Ieuan – We were then contacted by a biogas plant in Oxfordshire because they had started to get high levels of toxic metals in their sludge. It didn’t take us long to figure out the reason was that a company supplied them with iron chemicals derived from waste materials which were teaming with potentially toxic elements (PTEs). Testing for PTEs is not only the responsible thing to do but it’s also mandatory to ensure it meets the standards of the Quality Protocol for Anaerobic Digestate (QP) and PAS 110. Cadmium, Chromium, Copper, Lead, Mercury, and Zinc levels have to be kept to very low concentrations to ensure digestate spread on fields is safe and doesn’t damage the environment.

Abbie – PTEs aside, were they getting any other problems with the plant?

Ieuan – Yes. Locals were complaining about the smell as the chemical they were using wasn’t controlling the H2S. They also started noticing damage to their CHP unit, and this was all within 12 months. When I came in they already had plenty of data so they knew their desired H2S levels and I had the formula to calculate the dose. Problem solved, straight away.

Abbie – Did you have to dose quite high initially to solve their problems?

Ieuan – Not at all. Regular consistent dosing will adjust the ppm to whatever the requirements are at the plant. Obviously the feedstock contents will vary and this can have an effect on the ppm but once the iron is present in the sludge it will do its job accordingly. Word soon spread of the success and more biogas plants followed.

Abbie – Is ferrous suitable for all biogas plants?

Ieuan – Well, you could use it in all them but if it’s a crop only site there wouldn’t be much point because normally there no H2S produced. Any combination of food waste, animal waste and crops at a plant will produce H2S and ferrous will do a great job at removing it. Along with all the other benefits it brings, it really is the best solution for biogas plants.

If you have any questions about this article or using ferrous chloride at your plant, please feel free to contact us.