Sewage Works to Biogas Plants and Ferrous vs Ferric

I’d never have imagined that one day I would interview my dad, the water scientist, but I have and here it is.

In this part, we explore his beginnings in water treatment and how it led to exploring the biogas market.

Abbie – Starting from the beginning, what is your chemistry background?

Ieuan – In 1973 I was planning on going to Bath Uni to do a pharmacy degree, but that didn’t happen. Just before leaving sixth form at school, I was chatting to a lab assistant about a TV programme we’d both seen about the sewage industry struggling to find new recruits. I suppose the stigma of working with sewage didn’t appeal to most people but it didn’t bother me one jot. Anyway, she said she knew someone who was indeed struggling to find new chemists at the local sewage works. This all lead to me being offered employment at what is now Severn Trent. At the time it was called Upper Stour Main Drainage Authority. They offered me a wage, and to pay for my education, which equated to one day per week at college. At age 20 being offered money instead of having to find it for my education was very appealing. So that’s where I got my HNC and went on to do my GRIC.

Abbie – What kind of work did you do during that time?

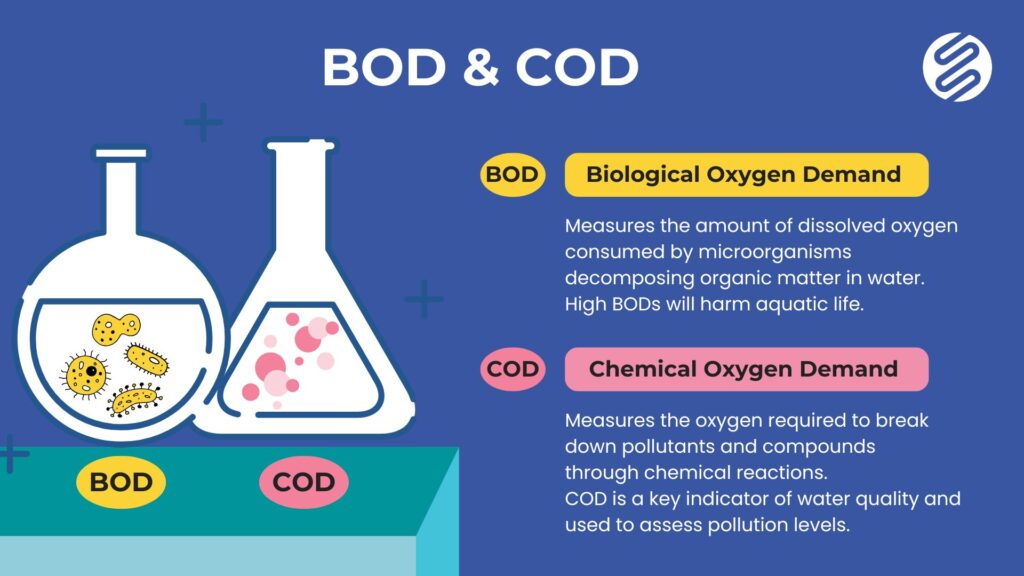

Ieuan – I was in the lab, analysing sewage basically, learning on the job. The first topics we studied were things like free nitrogen and ammoniacal nitrogen, Biological Oxygen Demand (BODs), Chemical Oxygen Demand (CODs), and Permanganate Value (PVs). All of which are ways of assessing the impact that sewage has on water.

Ieuan – We looked after the River Severn and its tributaries as it came through a good chunk of the Midlands. There were very strict controls as the authorities were really on the ball then. Remember there was salmon swimming up the Severn?

Abbie – Well I wasn’t alive then.

Ieuan – Well no, but one has to remember that there WAS salmon in the Severn and it also started coming up the Thames as it was cleaned up. We took our jobs very seriously.

Abbie – When did you come out of the lab?

Ieuan – In 1975, I became an operational chemist.

Ieuan – I was still doing lab work but I was also doing more hands on stuff outdoors. I’d spend summers sat on top of a digester with a manometer and gas analyser literally analysing the gas that came out of it. I would identify a problem and try to figure out what was going wrong. If a sewage works was failing to meet their standards they’d stick me in there. I’d put in my recommendations, usually carry them out myself and hopefully everything would start to work again properly. It wasn’t just the sewage and final effluent, I also tended to the sludge, the digestion, everything and anything to do with wastewater.

Abbie – So you really know your shi… sewage.

Ieuan – Ha! Yes, I suppose so. Later on I did a research project on septicity in rising mains which got published in the International Water Pollution Congress Journal. In fact I won a prize for that. They then asked me to do a second paper, and as a result of doing that two things happened. First of all they gave me the opportunity to enrol on a PhD course and secondly I was offered a job with E&A West.

Abbie – What did E&A West do?

Ieuan – They made chemicals, iron salts, iron sulphate etc. It was at Wests where I met Harry, and in 1986 we set up our old business ‘High Chemicals’ with Andrew.

Abbie – When did ferrous chloride come into the picture?

Ieuan – In the 80s, via British steel. If you pickle steel you can do it two ways. You can use sulfuric acid, in which case you’ll get ferrous sulphate. Use hydrochloric acid and you’ll get ferrous chloride. British Steel pickled both ways so to speak. The sale of ferrous sulphate was already covered as they had customers for it. Whereas ferrous chloride they used to destroy as nobody knew what to do with or had sold it before. We set up High Chemicals to make use of their waste materials, i.e. selling ferrous and ferric chloride.

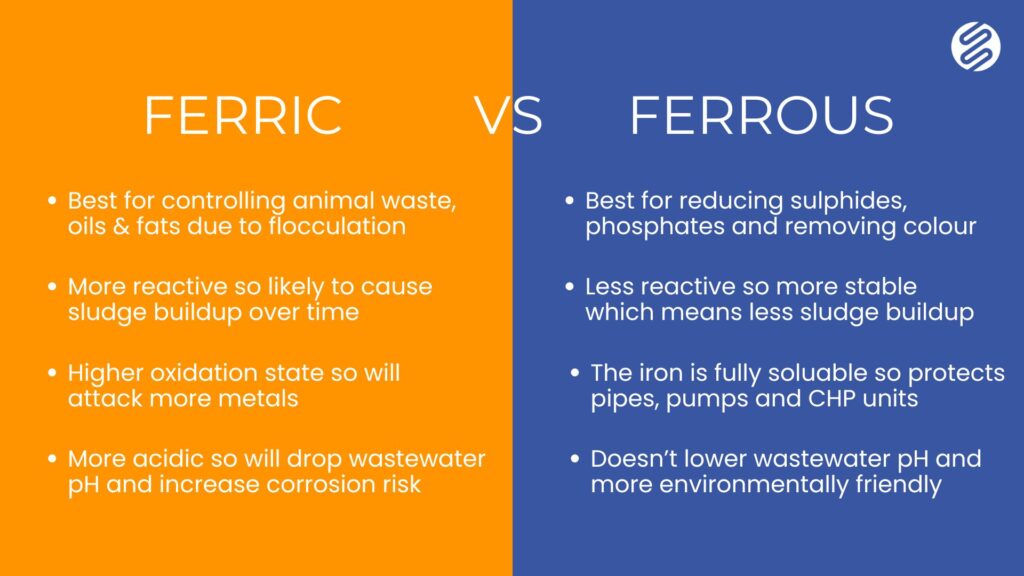

Abbie – What are the key differences between ferric and ferrous for the end user?

Ieuan – Ferrous is generally better for phosphate removal, but if you’re treating mostly animal waste, blood, oils and fats, then ferric is more effective. This due to ferric having a higher oxidation form and it is more acidic than ferrous. When you put ferric into anything containing oils or fats, it splits them. The biggest problem you’ve got with oils and fats is that they emulsify. In sewers they’ll get carried along in a sort of a solution which has a huge impact on the water course and will cause fatbergs. It’s a very high BOD, oxygen demand. If, you lower the pH of the waste using ferric you’ll split the oils and fats to form clumps that will settle out.

When purifying water in treatment works, adding a flocculant, i.e. ferric to the river water will settle it out, resulting in clean water. Ferrous doesn’t work as well for oils and fats because it’s not acidic enough. That said, for food types high in protein that aren’t fatty or contain an oxidising agent, ferrous chloride works incredibly well. In short, ferrous is better for treating phosphates and sulphides and for colour removal. It’s also worth noting that because ferrous isn’t as acidic as ferric it means it’s more environmentally friendly and reduces the risk of corrosion to pumps, pipes, CHP units etc.

Abbie – When did biogas plants start using our ferrous then?

Ieuan – Well, phosphate treatment resulted from research I carried out with Severn Trent and Anglian Water in the eighties. This led to the introduction of ferrous chloride being used on activated sludge plants (ASPs). Assisting with the anaerobic digestion process came later on. We started supplying ferrous chloride to biogas plants via High Chemicals in the nineties. Biogas generation was in its infancy then. The project we supplied was a joint venture between Severn Trent Water and East Midlands Electricity Company. It during this time that we developed the formula to remove hydrogen sulphide from biogas…

The next part of the interview, exploring the biogas industry will be posted soon. In the meantime, if you have any questions for us regarding water treatment please don’t hesitate to contact us.